The Significance of Top Quality in the Production of Copper Products

The value of high quality in the manufacturing of copper products expands far beyond plain conformity; it is indispensable to optimizing performance across different sectors. As we discover the diverse nature of top quality, the inquiry occurs: exactly how can makers stabilize these challenges to attain quality?

Effect On Product Performance

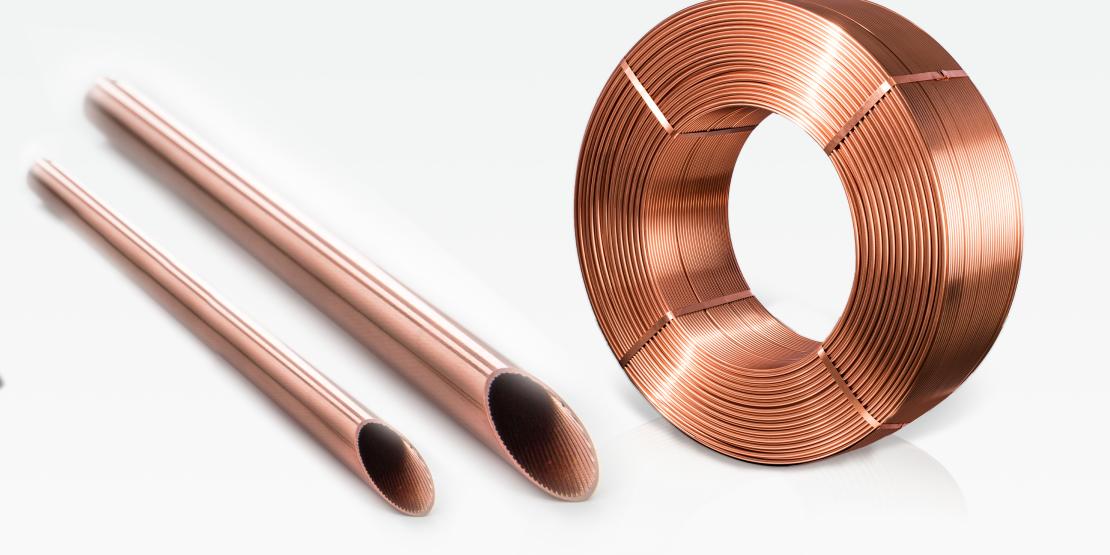

The top quality of copper products plays a critical function in determining their overall efficiency in different applications. Premium copper exhibits remarkable electrical conductivity, thermal conductivity, and deterioration resistance, which are important characteristics for sectors such as electronics, construction, and automotive. In electrical applications, for example, high-purity copper reduces power loss during transmission, ensuring reliable power distribution. This effectiveness is vital for the longevity and integrity of electric systems.

Furthermore, the mechanical buildings of copper, consisting of ductility and tensile stamina, greatly affect its performance in producing procedures. Copper items that meet stringent high quality standards can withstand considerable tension without deforming, consequently enhancing sturdiness and lowering the possibility of failure sought after environments.

Additionally, the surface finish of copper products effects their performance. A smooth, well-treated surface area can prevent oxidation and other types of degradation, ultimately prolonging the life of the component. In summary, the high quality of copper products straight influences their functionality, integrity, and long life throughout different markets, making it crucial for suppliers to comply with extensive quality control actions throughout the manufacturing procedure.

Expense Ramifications mediocre

Buying high-grade copper items is essential, as the price effects mediocre can be substantial for end-users and makers alike. Low quality copper can lead to raised failing prices, resulting in pricey repair services and substitutes. Manufacturers might encounter significant downtime as malfunctioning products demand remembers or rework, interrupting production routines and influencing general performance.

From an end-user viewpoint, the ramifications are just as serious. Poor-quality copper can lead to inefficiencies and raised operational expenses, as devices may require more constant maintenance. Ultimately, the first cost savings gotten from selecting lower-quality copper items can be eclipsed by these long-lasting expenses, making the pursuit of high quality not just a matter of performance, yet a vital financial consideration in the production sector.

Safety And Security and Conformity Requirements

Ensuring safety and security and compliance requirements in the manufacturing of copper products is important to preserving operational stability and shielding both workers and customers. The production procedure need to stick to rigorous regulations established forth by companies such as the Occupational Safety And Security and Health And Wellness Management (OSHA) and the Environmental Protection Firm (EPA) These regulations describe vital safety methods, including correct handling of raw materials and waste management, ensuring a safe job environment.

In addition, compliance with market standards such as ASTM International and ISO certification is important. These companies offer standards that aid producers execute finest techniques in high quality this article control and precaution. Routine audits and evaluations must be conducted to make sure adherence to these requirements, as non-compliance can lead to hazardous conditions and prospective lawful ramifications.

Customer Trust and Satisfaction

Count on and complete satisfaction among consumers play a critical function in the success of copper item producers (Copper Products). High-grade copper items not just meet strict market criteria however also meet consumer expectations, promoting loyalty and repeat organization. When customers are certain in the quality of the items they buy, they are most likely to create a lasting connection with the supplier, which can cause references and positive word-of-mouth

To construct this depend on, suppliers need to focus on quality control throughout the production process, making certain that each copper thing satisfies or exceeds specifications. Openness in manufacturing methods, coupled with dedication to customer support, strengthens the assumption of reliability. Timely delivery and responsiveness to customer questions substantially improve informative post satisfaction levels.

Customer responses should be proactively looked for and integrated right into product growth cycles to continually improve offerings. Engaging consumers in dialogue regarding their requirements and choices grows a feeling of collaboration, more strengthening their count on the supplier. Ultimately, a reputation for high quality and customer-centric practices distinguishes successful copper product makers in a competitive market, preparing for enduring client connections.

Long-lasting Company Success

A producer's dedication to top quality is indispensable to accomplishing long-lasting organization success in the affordable copper products market. Premium items foster customer loyalty, guaranteeing repeat business and favorable referrals that drive development. In a sector where dependability and efficiency are critical, firms that prioritize quality over cost-cutting steps are most likely to stand apart.

Moreover, consistent high quality decreases the occurrence of problems and rework, causing reduced functional prices and enhanced efficiency. This structured manufacturing process enables producers to assign resources successfully, permitting financial investments in innovation and innovation. Companies that adjust to market changes and invest in high quality improvements are much better placed to meet progressing customer needs.

Furthermore, maintaining rigorous top quality requirements enhances a company's reputation, attracting possible partnerships and brand-new customers. A robust online reputation for quality can work as a differentiator in crowded markets, opening doors to lucrative agreements and partnerships.

Inevitably, an unfaltering commitment to quality not only makes sure compliance with market laws yet additionally grows a sustainable business design. By embedding high quality right into every aspect of the production process, business can protect their location as leaders in the copper products market, paving the method for sustaining success.

Verdict

In conclusion, the relevance of top quality in copper product manufacturing is vital. As industries progressively count on copper for essential applications, maintaining strenuous high quality control is necessary to protect an affordable advantage and support a trusted market existence.

The importance of top quality in the manufacturing of copper products prolongs far past simple compliance; it is integral to maximizing efficiency across different industries. In summary, the quality of copper products directly impacts their capability, reliability, and durability across numerous markets, making navigate here it essential for manufacturers to stick to extensive top quality control actions throughout the manufacturing process.

A maker's commitment to top quality is essential to accomplishing long-term service success in the competitive copper products market.