How Hot Halves can Save You Time, Stress, and Money.

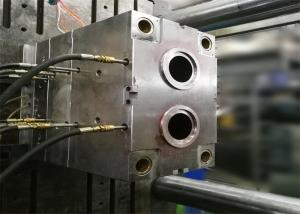

The 3 mentioned negative aspects can be enhanced with the acquisition of premium heating elements, hot runner plates and also nozzles, with careful maintenance during production. Benefits of the Hot runner mold and mildew (1 ). The size of a warm jogger is generally bigger, as well as the thaw is maintained a high temperature in the warm jogger.

( 2 ). The chilly jogger mold and mildew tends to have a too long cycle time since it is as well thick contrasted to the item. In such circumstances, a warm runner has a much shorter cycle time due to the fact that it does not need to be cooled down and solidified. (3 ). Conserving the raw material as well as decreasing product price are one of the most famous attributes of the warm jogger mold - hot halves.

Since the plastic is always in a liquified state in a warm jogger mold and mildew, the product gateway does not require to be cut, and basically no waste is generated, to ensure that a big quantity of resources can be saved. Given that no waste recycling, choice, squashing, dyeing or various other process actions are required, it has the ability to save labor, time, and also energy, hence minimizing usage.

When combined with the valve entrance, the hot runner system has the ability to alter the filling up pattern, remove or transfer weld lines, air traps, and so forth. (5 ). Streamlined operation and reduced molding cycle are additionally essential features of a hot jogger mold and mildew. Contrasted with the cool runner, the opening as well as closing stroke is decreased, which not just reduces the demolding and also molding cycles of the workpiece, yet additionally helps with automatic manufacturing.

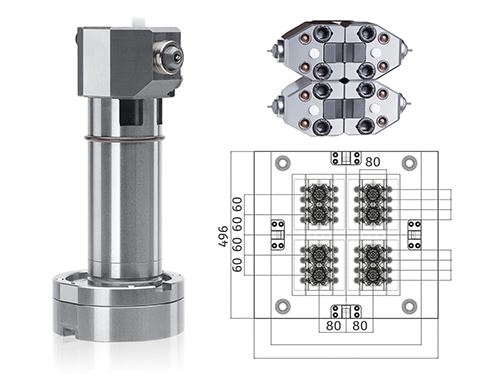

Multi-tip nozzle for straight injection KS 5 Injection moulding of small accuracy parts, with decreased distance in between axes Tiny mould systems application Single components with concentricity is aided by feeding the part through numerous entrances. Multi-tip nozzle for side gateway shot KS 8 Injection moulding of small accuracy parts, with lowered range in between axes Tiny mould systems application Inner component injection in order to accomplish excellent concentricity.

Hot Halves - Truths

Heaven Rheo-Pro ® warm jogger nozzle represents remarkable workmanship and also much better customer treatment Patented Heating system Technology Quick accessibility to the heating unit lowers equipment down time. If an excellent heater is an exchangeable heater, after that the most effective heating unit is one that can be changed extremely swiftly, ideally within minutes while the mold and mildew remains in the molding maker.

These are after that conveniently accessible. Nozzles with completely incorporated or merged heating unit components are not repairable. As soon as the heating system is dead, the entire nozzle needs to be removed as well as changed. That implies the whole mold and mildew should be gotten of the device so the warm runner manifold can be dismantled. hot halves.

Exchangeable nozzle heaters are as important in a shot mold and mildew as changeable stimulate plugs remain in the engine block of your car. A specifically well crafted nozzle heating system is one in which the heating unit housing or sleeve is self-clamping to make sure that it tightens snug around the nozzle body as the heating system heats up to reach a consistent nozzle set temperature level.

Delicate plastic products as well as additives with a slim temperature processing window can be built. Rheo-Pro ® Nozzle Collection Quick Facts · Smallest nozzle removed - 16 mm · Closest warm idea gate range - 17.8 mm · Closest shutoff entrance distance - 17.8 mm · Biggest nozzle melt birthed - 30 mm · Biggest nozzles - 1000 mm.

The Buzz on Hot Halves

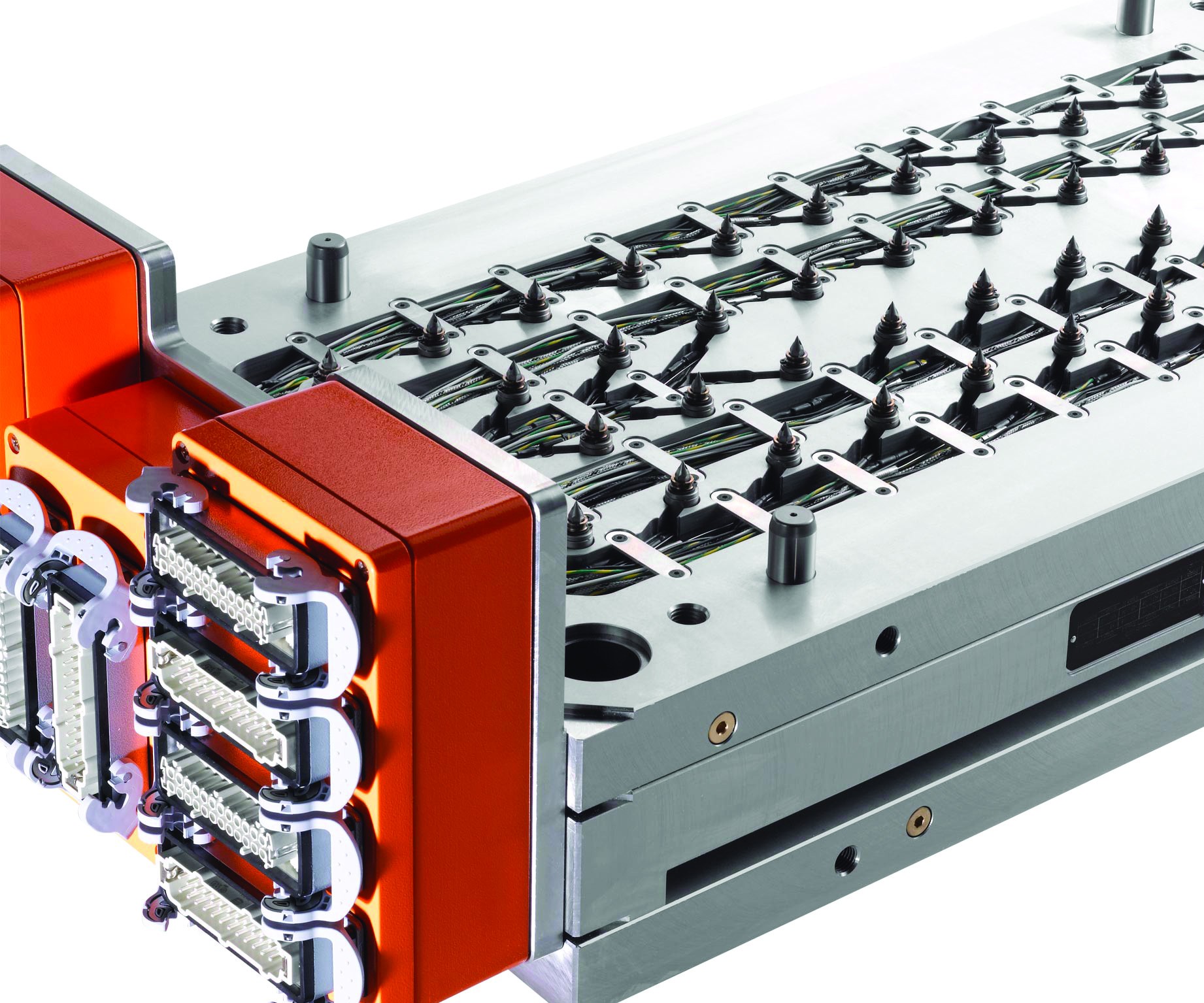

AREA OF THE CREATION This development associates with a shot molding apparatus as well as, more particularly, to a multi-cavity injection molding apparatus that consists of a well balanced warm runner design in a stack mold or manifold. BACKGROUND OF THE INNOVATION Using stack mold and mildews and also manifolds in a hot runner shot molding device is well recognized.

Harmonizing of the runner system results in on the whole greater top quality molded components since uniformity is achieved from mold and mildew tooth cavity to mold dental caries in a multi-cavity application. Also in multi-runner, single cavity applications, the benefits of harmonizing are well known as well as essential. A popular strategy for balancing a manifold or pile mold is to match runner sizes and also lengths as well as to match the number of turns in the joggers, to make sure that the pressure decline with the manifold or pile mold and mildew to every tooth cavity coincides.

This is at the very least partially due to a combination of shear heating of the thaw circulation incorporated with the design of the runner system. When melt is compelled under stress via a birthed, as is done in a hot runner system whether in a manifold or a stack mold and mildew, the thaw experiences rubbing or shear in the area nearby to the network wall surface.

The outcome is a differential in temperature level throughout the bore, with the center of the network being cooler than the product more detailed to the bore. Several hot jogger systems split the melt flow from a primary runner via two or more second joggers. When this occurs, the warm distribution account in the melt is separated also.

official website pop over here you could try this out